Did you know that the quality of your wafer slicing can be significantly impacted by the cutting fluid you use? Precision cutting fluids are vital for ensuring smooth, efficient wafer cutting in semiconductor manufacturing. These specialized fluids not only cool and lubricate but also help keep the cutting zone clean.

In this article, we will explore the key functions of precision cutting fluids for wafers, how they improve cutting accuracy, and the impact of choosing the right fluid on production efficiency and yield.

What is Precision Cutting Fluid for Wafers?

Definition and Composition of Precision Cutting Fluid

Precision cutting fluids are specifically formulated to optimize the wafer slicing process. They consist of a combination of water, oils (mineral, synthetic, or vegetable-based), and other additives. These fluids are designed to perform three primary functions: cooling, lubrication, and debris removal.

The fluid’s composition varies based on its intended purpose and the specific cutting process. Water-based fluids are widely used for their excellent cooling properties, while synthetic fluids are designed for high-performance needs, offering superior lubrication and stability under high temperatures. Semi-synthetic fluids combine the benefits of both types, providing a balance between cost and efficiency.

Why Precision Cutting Fluids Are Crucial for Wafer Processing

Precision cutting fluids are crucial for maintaining the structural integrity of the wafer during slicing. They reduce the friction between the cutting tool and the wafer, helping to produce smooth cuts without damaging the wafer's surface. Furthermore, they regulate temperature, which prevents the wafer from overheating and warping. Without the proper fluid, the cutting process could lead to excessive tool wear, defects in the wafer, and lower yields.

Cooling Properties of Precision Cutting Fluids

Heat Dissipation and Temperature Control

One of the most important functions of precision cutting fluids is their ability to control the heat generated during wafer slicing. The high-speed rotation of the cutting tool, especially diamond blades, generates significant heat. Without cooling, this heat can cause the wafer to expand, crack, or form microcracks, compromising the quality of the wafer.

Precision cutting fluids dissipate this heat, ensuring the wafer remains at an optimal temperature during cutting. This cooling effect also helps maintain the stability of the cutting tools, reducing wear and extending their lifespan.

Maintaining Wafer Integrity

Effective cooling provided by precision cutting fluids prevents thermal distortion in the wafer. When heat is not properly managed, thermal expansion can cause cracks or warping. This, in turn, leads to defective chips that may fail during later stages of production. By keeping the wafer cool, cutting fluids help preserve its integrity, ensuring that the final products meet quality standards and minimizing waste.

Lubrication Benefits of Precision Cutting Fluids

Friction Reduction Between Cutting Tool and Wafer

Precision cutting fluids act as lubricants, reducing friction between the cutting tool and the wafer. This friction reduction allows for smoother cuts and less mechanical stress on both the cutting tool and the wafer. Lower friction reduces the likelihood of tool wear, allowing tools to last longer and maintain their effectiveness.

This function is especially important in high-precision wafer cutting, where even minor irregularities in the cut can lead to lower yields and wasted materials. By minimizing friction, cutting fluids help ensure that every wafer is sliced cleanly and efficiently.

Improving Cut Quality and Surface Finish

The lubrication provided by precision cutting fluids enhances the overall cut quality. By reducing friction, the fluid ensures a smoother, more precise cut, which is essential for maintaining the wafer's surface quality. This leads to fewer imperfections, such as chipping or rough edges, which can compromise the functionality of the individual chips later on.

Furthermore, the improved surface finish makes it easier to apply subsequent processes, such as etching or bonding, resulting in higher-quality semiconductor products.

Debris Removal and Particle Management in Wafer Cutting

Role of Cutting Fluids in Cleaning the Cutting Area

During the cutting process, fine debris, also known as 'swarf' is generated. This debris can accumulate in the cutting zone, affecting the quality of the wafer cut. Precision cutting fluids help manage this by flushing away debris, ensuring that the cutting area remains clean. The fluid suspends the particles and carries them away from the cutting interface, preventing them from being re-deposited onto the wafer's surface.

This cleaning action is essential for maintaining the cleanliness of the wafer and avoiding defects that could arise from particle contamination. In semiconductor manufacturing, even tiny particles can lead to significant issues, including faulty chips and lower yields.

Ensuring Clean and Contaminant-Free Wafers

The use of precision cutting fluids helps prevent contamination of the wafer during the cutting process. By managing the debris effectively, these fluids ensure that the wafer's surface remains free of contaminants, which is critical for maintaining product quality. Contaminants left on the wafer could lead to surface defects, impacting the functionality of the final semiconductor devices.

Types of Precision Cutting Fluids for Wafer Dicing

Straight Oils and Their Applications

Straight oils, also known as neat-cutting oils, are commonly used in wafer cutting processes due to their excellent lubrication properties. These oils are derived from mineral or vegetable sources and provide superior lubrication, reducing friction between the cutting tool and the wafer. However, straight oils have limited cooling capabilities and may require additional cleaning after the cutting process.

Soluble Oils for Enhanced Cooling and Lubrication

Soluble oils, also known as emulsifiable oils, combine mineral or synthetic oils with emulsifiers, allowing them to mix with water. These oils offer excellent cooling and lubrication properties, making them ideal for wafer cutting processes that require both cooling and lubrication. They also help to extend tool life and prevent rust and corrosion, which is essential for maintaining the cutting equipment's performance.

Synthetic and Semi-Synthetic Fluids for High-Performance Needs

Synthetic fluids are formulated with chemical compounds designed to provide superior cooling and lubrication under high-temperature conditions. These fluids are particularly useful in applications that generate a lot of heat, such as when cutting hard or brittle materials. Semi-synthetic fluids combine the benefits of both water-based and synthetic fluids, offering a balance of cooling, lubrication, and cost-effectiveness.

Advances in Wafer Cutting Fluids: Novel Innovations

Water-Based Cutting Fluids and Sustainability

Water-based cutting fluids are gaining popularity due to their environmentally friendly properties. These fluids are biodegradable, non-toxic, and safe for the environment. Water-based fluids are ideal for wafer cutting applications where cooling is the primary concern. Companies are increasingly adopting these fluids to reduce their environmental footprint while maintaining performance.

Innovative Cooling and Lubricating Fluids

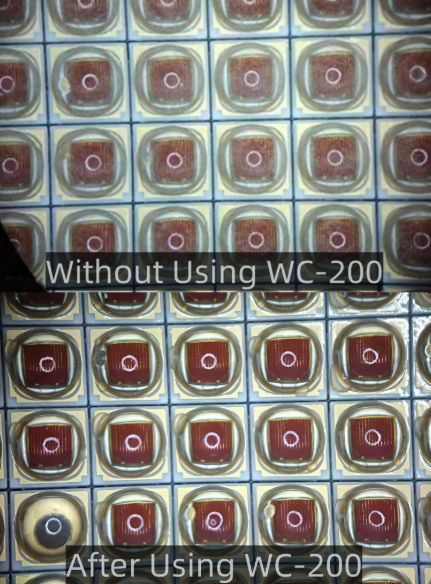

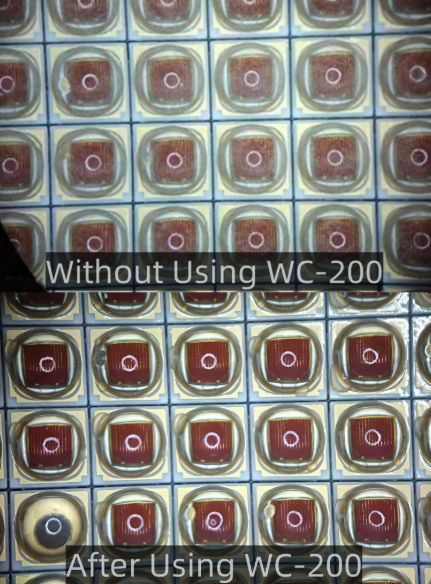

Companies like BASF have developed advanced wafer cutting fluids that combine cooling and lubricating properties with chemical additives designed to improve cutting precision. These innovative fluids help reduce saw damage and enhance the overall dicing process. As wafer slicing technology continues to evolve, new cutting fluid formulations are improving both the quality and efficiency of the manufacturing process.

Surface Tension-Free Dicing Fluids and Their Impact

Innovations like surface tension-free dicing fluids, such as Keteca Diamaflow, are also transforming the industry. These fluids reduce water's surface tension, preventing dry spots and ensuring that the wafer is evenly wetted during cutting. This reduction in friction leads to higher throughput and improved cut quality, resulting in more efficient and cost-effective wafer slicing.

Selecting the Right Precision Cutting Fluid for Your Wafer Cutting Needs

Factors to Consider When Choosing Cutting Fluids

When selecting the right precision cutting fluid for wafer slicing, several factors must be considered. These include the material of the wafer, the cutting method, and the specific requirements of the cutting process. Additionally, environmental regulations, fluid cost, and the desired performance characteristics should all play a role in the decision-making process.

Collaborating with Fluid Suppliers for Optimal Results

To find the best cutting fluid for your wafer slicing needs, it's essential to work closely with fluid suppliers. Suppliers can provide valuable insights into the most effective fluid formulations for your specific processes. Trials and testing should be conducted to assess the fluid's performance under real-world conditions.

Conclusion

Precision cutting fluids play a vital role in wafer slicing, offering essential benefits like cooling, lubrication, and debris removal. These fluids help maintain wafer quality and maximize yields. By choosing the right fluid, you can improve tool life and wafer integrity. As the semiconductor industry advances, cutting fluid technology will continue to evolve, meeting the growing need for precision and efficiency.

Yuanan's Precision Cutting Fluid for Wafers offers unique benefits with non-corrosive properties, ensuring better performance and longer-lasting tools for the wafer cutting process.

FAQ

Q: What is Precision Cutting Fluid for Wafers?

A: Precision cutting fluid for wafers is a specialized fluid designed to cool, lubricate, and clean the cutting zone during wafer slicing. It helps improve cutting precision, tool life, and wafer quality.

Q: How does Precision Cutting Fluid for Wafers improve the cutting process?

A: It reduces friction, preventing tool wear, while also dissipating heat to prevent wafer distortion. This results in smoother cuts, better surface finish, and higher yields.

Q: What are the benefits of using Precision cutting fluid for wafer slicing?

A: It enhances cooling, lubrication, and debris removal, which ultimately improves wafer integrity, tool lifespan, and overall efficiency in the slicing process.