In the demanding world of high-temperature metalworking, the pursuit of efficiency has long been overshadowed by a persistent, dark reality: the mess of graphite. For decades, manufacturers operating in the 300°C to 1000°C range—especially those specializing in high-pressure die casting and precision forging—have been forced into a difficult compromise. While traditional organic lubricants fail under intense heat, their only alternative—graphite—leaves a legacy of soot, grime, and hidden costs.

Traditional graphite-based forging process showing black soot accumulation and messy factory environment issues.

Today, as global supply chains shift toward sustainability and high-precision electronics, this "dirty" compromise is no longer sustainable. The emergence of the 3900B-14 series marks the beginning of a "White Revolution," proving that high-temperature performance and a pristine factory environment are no longer mutually exclusive.

The 300°C Barrier: Where Tradition Fails

To understand the necessity of 3900B-14, one must first understand the technical gap in modern lubrication. Most conventional organic polymer-based release agents are designed for low-to-medium temperature applications. They perform admirably until the mold temperature hits approximately 300°C. At this threshold, these organic compounds undergo carbonization—they literally burn away, leaving behind carbon deposits that foul the mold and compromise the integrity of the workpiece.

For industries producing thin-wall magnesium die casting or intricate aluminum components—where process temperatures frequently exceed 400°C—the failure of organic lubricants historically meant a forced transition to graphite. While graphite is thermally stable, it is an industrial pollutant that coats everything it touches in a conductive black film.

Comparison of industrial mold contamination, showing heavy soot and dirty workspace caused by conventional graphite lubricants versus the clean-running alternative.

High-precision aluminum die casting part using 3900B-14 release agent, demonstrating a clean, bright surface finish without carbon residue.

The Hidden Costs of a "Black" Workshop

Many factory managers view graphite as a "cheap" solution, but this is a calculation that ignores the massive latent costs. A graphite-heavy environment isn't just an aesthetic issue; it's a productivity killer for precision automotive components manufacturers.

First, there is the equipment risk. Graphite dust is highly conductive. When it permeates the electronics of modern CNC machines and robotic arms, it causes short circuits and premature component failure. Second, there is the operational downtime. Graphite accumulation on molds requires frequent mechanical cleaning, which halts the entire production line. By switching to the clean-running 3900B-14, manufacturers report a significant post-processing reduction and lower mold maintenance frequency. This translates to higher OEE (Overall Equipment Effectiveness) and a lower total cost per part, despite the premium nature of the chemistry. Finally, there is the brand impact. Top-tier clients in the electronics and EV sectors don't just buy a product; they buy into a clean, controlled, and responsible manufacturing process.

Close-up of carbonization and mold build-up caused by low-quality graphite lubricants at temperatures above 300C.

The 3900B-14 Solution: Science Meets Cleanliness

The 3900B-14 series was engineered specifically to bridge the gap between "clean but weak" organics and "strong but dirty" graphite. The secret lies in its hybrid formulation. By combining high-purity Boron Nitride (BN)—often referred to as "White Graphite"—with a proprietary inorganic glass-forming lubricant, 3900B-14 achieves what was previously thought impossible.

Beyond mere heat resistance, the true technical marvel of 3900B-14 lies in its dynamic film-forming properties. While traditional coatings become brittle and flake under pressure, 3900B-14 acts as a fluid interface. As the metal deforms during forging (even at extreme temperatures like 960°C for Titanium), the glassy BN-film flows synchronously with the substrate. This ensures continuous coverage, effectively eliminating the micro-cracks and surface oxidation that typically plague high-value aerospace and medical-grade alloys.

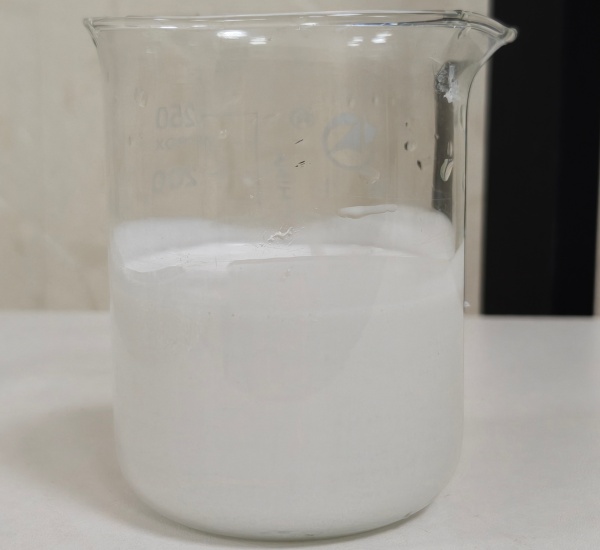

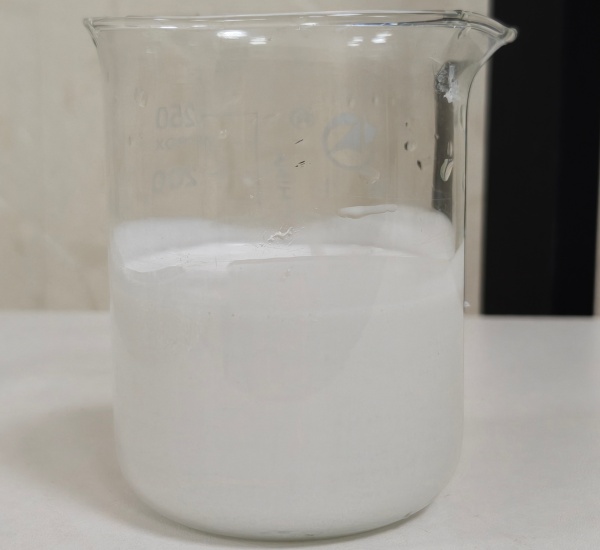

3900B-14 concentrated Boron Nitride release agent in a laboratory beaker, showing milky white inorganic formulation for high-temperature forging.

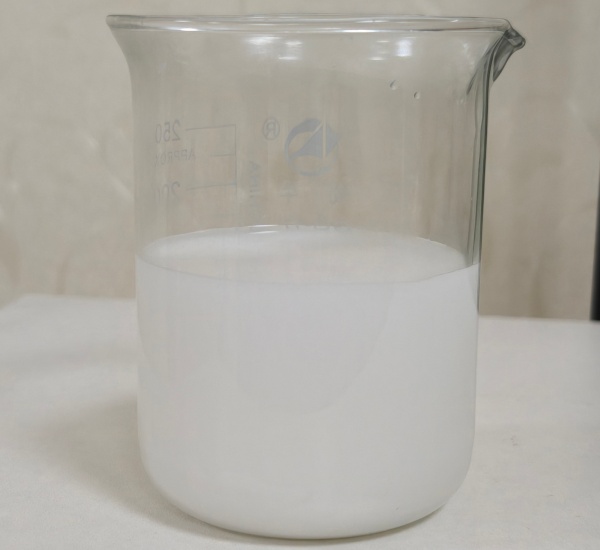

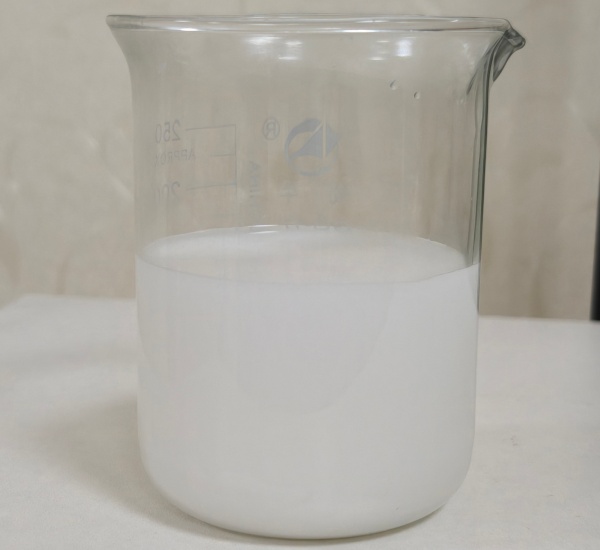

Diluted 3900B-14 water-based die casting lubricant, ready for automated spray systems in thin-wall magnesium alloy production.

Standardization as a Tool for Excellence

As we continue to innovate, we have listened to the feedback from the field. To eliminate the confusion of multiple sub-models, we have standardized our most advanced formulation as 3900B-14. This version represents the optimal balance of atomization performance, adhesion, and extreme-heat durability. Whether you are casting non-stick aluminum cookware or forging aerospace-grade titanium components, 3900B-14 provides a consistent, transparent solution that eliminates the guesswork from your production line.

Furthermore, for specialized applications like 3D curved glass or automotive windshield shaping, our dedicated 3900B-18 line applies the same "clean heat" philosophy to non-metallic substrates, ensuring that the future of complex geometry glass is as clear as the factories that produce it.

Conclusion: Investing in the "White Workshop"

The transition from a "Black Factory" to a "White Workshop" is more than just a cleanup—it is a strategic upgrade. By choosing 3900B-14, you are reducing secondary processing costs, protecting your high-end machinery, and positioning your brand as a leader in modern, sustainable manufacturing. In the competitive landscape of the next decade, cleanliness isn't just a virtue; it is a measurable competitive advantage.

Call to Action

Ready to clean up your production and level up your brand?

Don't let outdated lubrication methods hold back your factory's potential. Join the "White Revolution" today and see the difference that 3900B-14 can make for your process, your people, and your bottom line.

[Contact Our Technical Team] for a customized lubrication audit or to request a sample of the 3900B-14. Let's build a cleaner, brighter future for manufacturing together.

Frequently Asked Questions (FAQ)

Q1: How does 3900B-14 compare to traditional graphite lubricants in terms of cost-efficiency?

A1: While the per-unit cost of 3900B-14 may be higher than raw graphite, the total cost of ownership is significantly lower. By eliminating the need for intensive post-casting cleaning and reducing the frequency of mold maintenance, manufacturers typically see a 15-20% increase in OEE (Overall Equipment Effectiveness). Additionally, it protects expensive CNC equipment from conductive graphite dust, preventing costly electronic repairs.

Q2: Can 3900B-14 be used on existing spray systems for thin-wall die casting?

A2:Yes. 3900B-14 is formulated for excellent atomization. It can be integrated into most automated or manual spray systems used in magnesium and aluminum die-casting lines without major hardware modifications. Its superior adhesion ensures a uniform protective film even on complex, high-depth mold geometries.

Q3: Does this product comply with international environmental standards like RoHS or REACH?

A3: Absolutely. 3900B-14 is a clean, Boron Nitride-based formula that is fully compliant with RoHS 2.0 and REACH SVHC standards. This makes it an ideal choice for factories in Southeast Asia that supply components to global electronics and automotive brands requiring strict environmental documentation.

Q4: What is the maximum operating temperature for 3900B-14 in titanium forging?

A4: 3900B-14 is designed to withstand extreme thermal stress. In titanium alloy forging, it remains stable and lubricious at temperatures as high as 960°C to 1000°C. It forms a glassy, non-reactive barrier that effectively prevents surface oxidation and hydrogen embrittlement during the heating and deformation process.

Q5: Will 3900B-14 leave carbon residues on the surface of non-stick cookware or high-precision parts?

A5:No. Unlike organic lubricants (such as 8006 or 8100 series) that carbonize and turn black above 300°C, 3900B-14 is inorganic. It remains a clean, white/transparent film throughout the thermal cycle, ensuring that products like non-stick aluminum cookware or polished electronic frames maintain a bright, high-quality surface finish right out of the mold.