In high-precision industries like medical devices, optical manufacturing, and electronics assembly, silicone residue removal is a persistent headache. Traditional cleaners force manufacturers into a tough choice: even slightly alkaline formulas corrode sensitive materials, while silicone-targeted cleaners with silicone-based additives leave harmful residues. For small and medium-sized enterprises (SMEs) focused on global compliance and tight production budgets, this dilemma often hinders efficiency and export opportunities.

A survey by the International Precision Cleaning Association (IPCA) shows that 41% of electronics manufacturers have faced rejected orders due to silicone contamination, and 35% of medical device makers have scrapped workpieces from corrosive cleaners. The good news? Many common misconceptions about silicone cleaning are holding back better solutions—solutions like Shenzhen Yuanan Technology's 6683, which balances cleaning power, material protection, and global compliance without compromise.

Myth 1: Neutral Cleaners Can't Handle Tough Silicone Residue

The Truth: Advanced neutral formulas like 6683 outperform harsh alternatives for precision cleaning

Many manufacturers assume "neutral" equals "weak," but modern composite formulas have shattered this stereotype. Even slightly alkaline cleaners (pH 8-9)—often marketed as "mild"—can corrode aluminum, copper, and plastic components over repeated use. For SMEs processing sensitive metals, this translates to an average of $3,000 monthly in scrapped parts, according to IPCA's 2024 report.

Shenzhen Yuanan's 6683, a true neutral silicone-specific cleaner (pH 6.5±0.5), offers a better path. Its targeted emulsifiers bind specifically to silicone molecules, lifting residues without attacking base materials. Unlike slightly alkaline options, 6683 maintains the integrity of sensitive components like optical glass lenses or delicate metal parts, reducing yield loss from 8-10% to less than 1%.

For SMEs processing automotive electronics or consumer tech, this balance is critical. 6683 eliminates the need to choose between "clean enough" and "undamaged parts"—a win for both production efficiency and product quality, even for high-volume assembly lines.

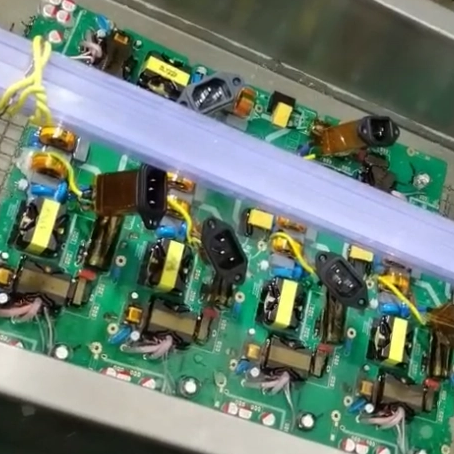

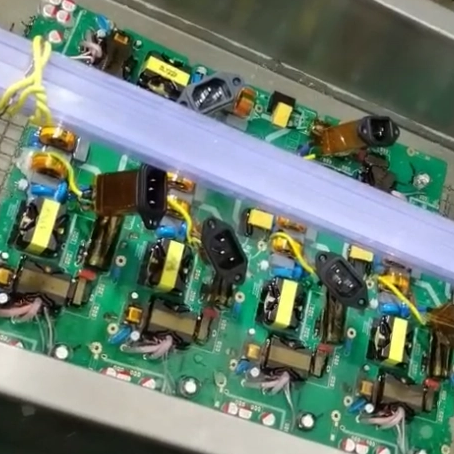

methanol-free cleaner for power device cleaning - residue-free result for electronics manufacturing

silicone-free cleaner for power device cleaning - structural cleanliness for electronic component manufacturing

Myth 2: Silicone-Targeted Cleaners Require Silicone Additives to Work

The Truth: 6683 delivers comparable (or better) results with silicone-free defoaming

Most silicone-targeted cleaners on the market rely on silicone-based defoamers to help dissolve silicone residues. While this approach improves initial cleaning performance, it creates a hidden risk: trace silicone from the defoamer remains on surfaces, ruining subsequent welding, bonding, or coating processes. This is a major pain point for electronics and medical device manufacturers, where even minute contamination can lead to product failures.

Shenzhen Yuanan's 6683 breaks this cycle with a silicone-free defoaming system. It eliminates foam without adding silicone, while its specialized emulsifiers deliver 25% higher silicone emulsification efficiency than conventional silicone-added cleaners (verified by third-party SGS testing). In real-world use, 6683 outperforms silicone-added alternatives on delicate materials like precision circuit boards and optical glass, where residue-free cleaning is non-negotiable.

For SMEs exporting to global markets, this means avoiding costly compliance violations and rework—all while maintaining the cleaning power needed for tough silicone residues.

Myth 3: Precision Cleaning for Medical/Optical Industries Demands Premium-Priced Imported Solutions

The Truth: Imported cleaners like 6683 can deliver precision performance at accessible costs for SMEs

Many SMEs in medical device and optical manufacturing hold a common misconception: “To meet the strict precision and safety requirements of our industry, we have to pay a premium for well-known imported cleaners.” This belief often leads them to overspend on big-brand imported products—even when those products come with unnecessary costs (like global brand markup, rigid packaging, or long lead times) that don't actually improve cleaning results.

The reality is that not all imported cleaners are overly expensive. Shenzhen Yuanan's 6683, while imported for most global markets, is designed specifically to address the cost and flexibility pain points of SMEs in precision industries. It matches the cleaning performance of premium imported alternatives (e.g., removing silicone residues without damaging materials) but cuts costs by 30%-40%—and offers more flexibility that aligns with how SMEs operate.

Key advantages of 6683 include:

-

Compliance with global standards: RoHS 2.0, ISO 9001, and ISO 14001 certifications, with no restricted harmful substances

-

Positive feedback from medical device manufacturers: Independent testing by medical equipment SMEs confirms safety and efficacy for sensitive applications

-

Adaptation to diverse conditions: Formulated for humid production environments, preventing recontamination

-

Flexible supply chains: Small-batch ordering (25L-200L) tailored to SME production volumes, with bulk options (IBC ton barrels) for scaling operations

For SMEs operating on tight margins, 6683 means accessing the same cleaning performance as large corporations without the premium price tag or long lead times of imported alternatives.

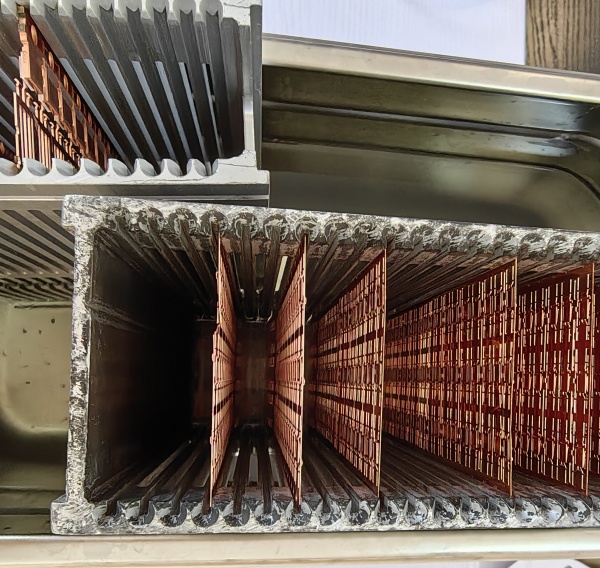

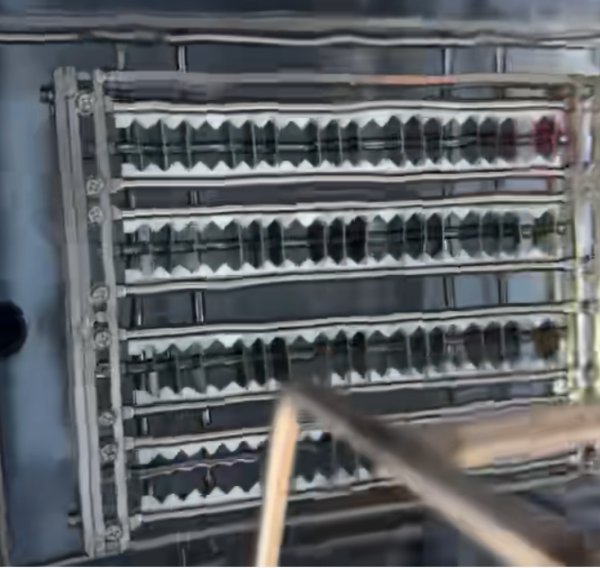

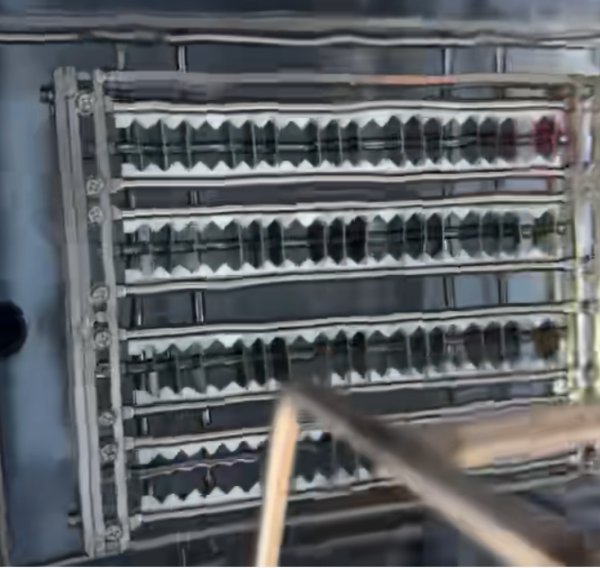

6683 silicone-free neutral cleaner cleans stainless steel precision internal components - high purity after cleaning for precision manufacturing

6683 scratch-free cleaner for LED package frame - high cleanliness after cleaning for LED manufacturing

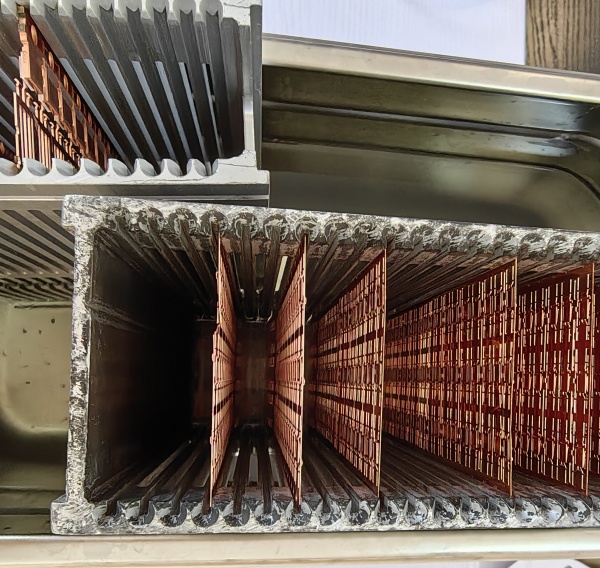

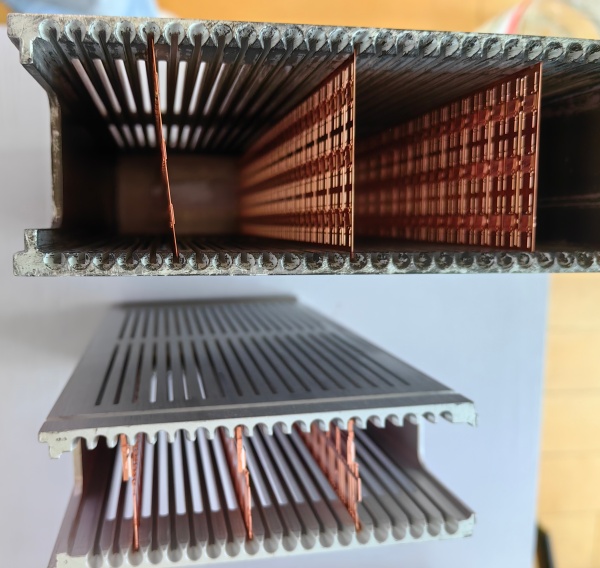

6683 industrial cleaner cleaning heat exchanger during process - residue removal for HVAC and cooling systems

Real-World Results: How SMEs Benefit from 6683's Neutral Silicone Cleaning

Case 1: Medical Device Component Manufacturer

A medium-sized enterprise specializing in ultrasonic medical device components struggled with silicone residue from mold release agents. Traditional silicone-targeted cleaners left trace silicone, interfering with the bonding of critical parts. Switching to 6683 resolved both issues:

-

Silicone removal rate reached 99.2%, passing 38# dyne pen cleanliness tests

-

No silicone residue, eliminating bonding failures and reducing rework costs by $2,100/month

-

Independent testing confirmed the product's safety for medical device applications, enabling export to global clients

Case 2: Aerospace Metal Processor

An SME focused on aerospace-grade titanium and aluminum components faced strict wastewater discharge regulations. Its previous alkaline cleaner required expensive treatment to meet environmental standards. Adopting 6683 delivered:

Effective removal of silicone residues without corroding high-value metal parts

Neutral formula allowed direct dilution for compliant discharge, cutting wastewater treatment costs by 60%

Met the enterprise's rigorous material protection requirements for aerospace applications

Case 3: Optical Instrument Manufacturer

An optical manufacturing SME producing precision lenses and optical components needed a cleaner that would remove silicone without scratching or damaging delicate surfaces. 6683 provided:

-

99.5% silicone residue removal with zero surface damage, maintaining optical clarity

-

Fast rinsing capability (water-only rinse) reduced processing time by 20%

-

Consistent performance across high-volume production runs, improving yield from 92% to 98.7%

Practical Guide: Choosing the Right Silicone Cleaner for Your SME

Key Selection Criteria (Why 6683 Stands Out)

-

pH Range: Opt for true neutral (pH 6.5±0.5) like 6683 to protect aluminum, copper, plastic, and optical materials

-

Composition: Ensure no silicone, methanol, or sodium p-toluenesulfonate—6683 meets all these requirements for process compatibility

-

Performance Metrics: Look for ≥25% higher silicone emulsification efficiency (6683's verified SGS-tested performance)

-

Compliance: Verify RoHS, ISO certifications, and positive feedback from industry-specific users (e.g., medical device manufacturers)

Recommended Application Methods for 6683

Material Type | Usage Concentration | Operation Mode | Processing Time |

Medical Devices | 3%-5% | Soaking | 5-10 minutes |

Optical Glass | 4%-6% | Spraying | 3-8 minutes |

Electronic Components | 5%-7% | Ultrasonic Cleaning | 2-5 minutes |

Call to Action (CTA)

Claim Free Resources: Download our 6683 Non-corrosive Eco-friendly Industrial Degreaser MSDS (with RoHS certification details) in our website by filling in your "company name + industry + contact information" via our website.

Book a Free Technical Diagnosis through Tel/WhatsApp/WeChat: +8618123969340 or Email to share your oxidation pain points—our team will provide a solution report within 24 hours.

Apply for a Sample Trial: Request a free 1015B sample (customized to your industry) and start verifying its performance in 3 days.

FAQ

Q1: How does 6683 perform for cleaning aluminum alloy parts in electronics assembly workshops?

A1: For SMEs focused on electronics manufacturing, 6683's true neutral formula (pH 6.5±0.5) solves the core pain point of "silicone residue disrupting welding and bonding." As a silicone-free neutral cleaner for consumer electronics assembly, it boasts an ultra-low corrosion rate of 0.001 g/(m²·h)—99% lower than mild alkaline alternatives—keeping sensitive metals like aluminum free from discoloration while achieving 99.2% silicone removal. It adapts seamlessly to common production environments, preventing recontamination after cleaning, and works perfectly with ultrasonic cleaning equipment widely used in electronics workshops. Local SMEs report cutting scrappage costs by 30% thanks to its balanced cleaning power and material protection.

Q2: Is 6683 suitable for medical device makers requiring residue-free cleaning?

A2: Absolutely. For SMEs producing medical devices (such as dental tools or ultrasonic components), 6683 meets strict safety expectations for precision medical component cleaning. It contains no methanol or sodium p-toluenesulfonate—verified by independent testing from medical manufacturers. Its targeted emulsification formula removes mold-release silicone residues without leaving traces, which is critical for subsequent bonding and sterilization compatibility in precision medical production. Classified as non-hazardous, it streamlines logistics processes, avoiding delays associated with harsher chemical cleaners.

Q3: Can 6683 meet the needs of optical glass manufacturers for safe and efficient cleaning?

A3: Yes. For SMEs specializing in optical glass (including solar panel glass and precision lenses), 6683 acts as a scratch-free silicone remover for optical lens processing. Its neutral formula simplifies wastewater management, eliminating the need for expensive treatment equipment and cutting related costs by 60% compared to alkaline cleaners. It delivers 99.5% silicone residue removal while preserving optical clarity—a must for high-precision optical applications. Its fast rinsing capability (water-only rinse) pairs well with common optical cleaning workflows, helping small-batch manufacturers boost production efficiency by 20%.

Q4: How does 6683 help automotive electronics SMEs reduce cleaning costs?

A4: For SMEs in the automotive electronics supply chain (producing parts like motor controllers), 6683 is a cost-effective neutral cleaner for automotive component soldering preparation. It matches the precision performance of premium imported alternatives but costs 30%-40% less, with no unnecessary brand markups. Its flexible packaging (25L/200L) aligns with SMEs' small-batch procurement needs, avoiding the forced over-purchasing common with traditional bulk cleaners. As a silicone-free solution, it ensures no residue interferes with welding processes, helping SMEs avoid costly order rejections from downstream clients.

Q5: What advantages does 6683 offer for aerospace metal processing SMEs?

A5: For SMEs handling aerospace-grade titanium and aluminum components, 6683 is a corrosion-free silicone remover for high-precision metal fabrication. Its neutral formula protects high-value aerospace metals from damage—critical for meeting the strict tolerance requirements of aerospace applications—while its silicone-free design ensures compatibility with subsequent coating and assembly steps. It aligns with environmental best practices, as its neutral wastewater is easy to manage without heavy disposal costs. Additionally, it integrates smoothly with common aerospace metal cleaning protocols, eliminating the need for specialized equipment upgrades.

Q6: How does 6683 address the welding compatibility needs of electronics SMEs?

A6: For SMEs manufacturing circuit boards or connectors, 6683 is a silicone-free neutral cleaner for electronics soldering compatibility. It solves the top pain point of "silicone residue causing weak welds"—a common issue in electronics export industries. Its non-silicone defoaming system leaves zero traces, and its neutral pH (6.5±0.5) protects tin-plated steel and brass components widely used in electronics enclosures. As an affordable precision solution, it works with the ultrasonic cleaners most workshops already use, requiring no additional equipment investments.