1. Global Market Overview

The global copper tubes market is experiencing steady and robust growth, propelled by cross-industry demand and regional industrial development. As per the Global Copper Tubes Market report, the market is forecast to expand at a Compound Annual Growth Rate (CAGR) of 7.9% from 2025 to 2030, with its value escalating from 29.14 billion in 2025 to 42.62 billion by 2030 (Global Copper Tubes Market Document, 2024). This growth is mainly driven by the booming HVAC (Heating, Ventilation, and Air Conditioning) sector, especially in emerging economies with increasing urbanization rates, the rapid expansion of the global automotive industry (particularly electric vehicles, EVs), and the growing utilization of copper tubes in renewable energy systems (such as solar thermal and geothermal applications) due to copper's excellent thermal conductivity and corrosion resistance (MarketsandMarkets, 2024).

From a regional perspective, the Asia-Pacific (APAC) region is the largest and fastest-growing market for copper tubes, accounting for over 50% of the global market share in 2024 (Global Copper Tubes Market Document, 2024). The region's dominance can be attributed to strong industrialization, rising infrastructure investments, and a surge in demand for residential and commercial HVAC systems. Within APAC, India and China stand out for their remarkable market performance. India's copper tube market is driven by rapid urbanization, a growing middle class, and government initiatives to promote affordable housing and smart city projects, all of which necessitate large quantities of copper tubes for plumbing and HVAC (Global Copper Tubes Market Document, 2024). China, on the other hand, is not only a major consumer but also the world's leading producer of copper tubes, supported by its mature manufacturing ecosystem, large-scale automotive production (it is the world's largest EV market), and continuous investments in green energy infrastructure (Global Copper Tubes Market Document, 2024).

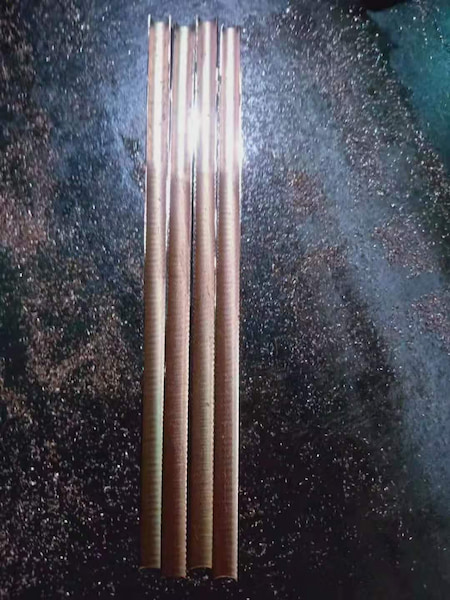

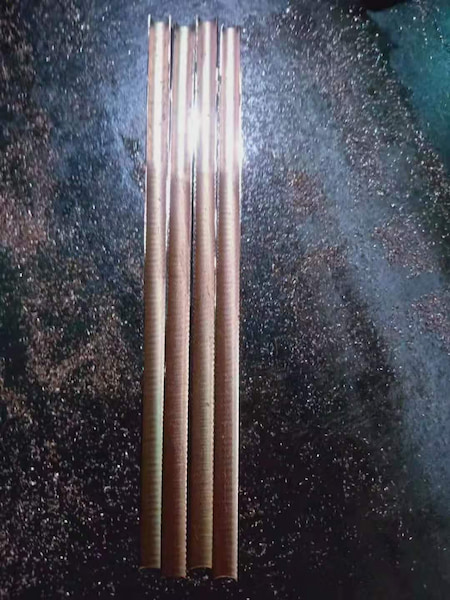

Rainy Season Anti Oxidation Copper Tube With Shenzhen Yuanan Fluid

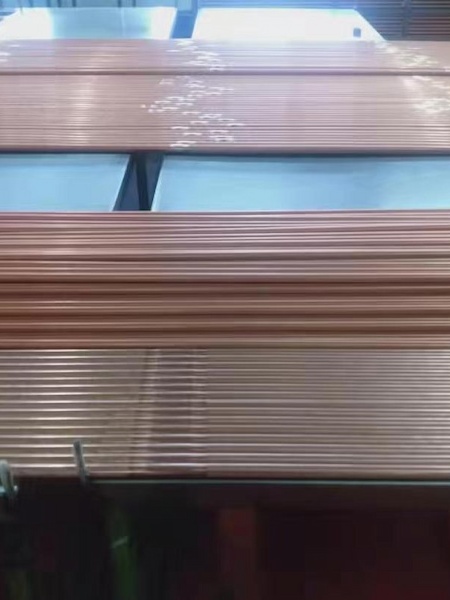

Cost Saving Copper Tube Processing Result With Yuanan Cutting Fluid

In China's highly competitive copper tube industry, two enterprises, Golden Dragon Precise Copper Tube Group and Hailiang Group, are at the forefront. Among them, Golden Dragon Precise Copper Tube Group (hereafter referred to as "Golden Dragon Group") is the world's largest precision copper tube manufacturer, boasting an annual production capacity of 650,000 tons (Global Copper Tubes Market Document, 2024). The group supplies to some of the world's most renowned brands, including Gree and Midea (leading global HVAC manufacturers) and BYD (one of the world's top EV producers). Its product portfolio encompasses precision copper tubes for HVAC, automotive air conditioning, refrigeration, and industrial heat exchange systems, making it a crucial player in supporting global supply chains for key industries.

2. Longfeng Precise Copper's Challenges

Longfeng Precision Copper Tube Co., Ltd., a core subsidiary of Golden Dragon Group, specializes in manufacturing high-precision copper tubes for high-end automotive and commercial HVAC applications. A significant portion of Longfeng's output is exported to Europe, North America, and Southeast Asia, where clients demand strict compliance with international quality standards. However, like many copper tube manufacturers in Southern China, Longfeng encountered major production obstacles during the annual "Meiyu Season" (plum rain season, from March to June). Persistent high humidity (averaging 85%—90%) led to rapid oxidation of copper tubes. Additionally, the use of improper cutting fluids caused oil sludge separation, jeopardizing its ability to meet export quality requirements.

During Southern China's Meiyu Season (the rainy season), with air humidity often exceeding 85% and reaching over 90% in some areas and periods, even corrosion-resistant copper tubes are prone to rust. In addition to copper pipes oxidizing during the rainy season, Longfeng also encountered another problem. When machining copper, copper chips and powder are inevitably generated. These copper particles enter the cutting fluid and form free copper ions. Copper ions do not directly increase the water hardness (the concentration of calcium and magnesium ions). Instead, they combine with anions in the water to form precipitates. This indirectly disrupts the dissolution equilibrium of calcium and magnesium salts. As a result, the concentration of free calcium and magnesium ions relatively increases. Most cutting fluids are not resistant to such changes in water quality. When the hardness-related conditions are triggered, it causes micro-emulsions in the cutting fluid to "break emulsion". This leads to stratification, with semi-oil and semi-water soap-like substances (i.e., oil sludge) floating on the surface. This not only affects the cleaning effect during processing but also results in the loss of lubricity.

The oil sludge separation brought far-reaching negative impacts on the production of copper tube:

Equipment blockage and wear: Oil sludge clogged the cutting fluid's circulation pipelines, nozzles, and filters, leading to reduced coolant flow and insufficient pressure. Poor heat dissipation in the cutting area accelerated tool wear and even caused tool breakage. Meanwhile, hard particles (such as copper powder and soap) in the oil sludge accelerated the wear of precision guide rails, bearings, and hydraulic pumps, shortening the service life of the equipment.

Deterioration of workpiece surface quality: Oil sludge adhered to the surface of copper tubes, resulting in oil stains, scratches, or color differences after processing. For pipes requiring high smoothness (such as refrigeration copper tubes), this posed a risk of scrapping. Moreover, residual oil sludge interfered with subsequent welding, electroplating, or coating processes, reducing product yield.

Deterioration of cutting fluid performance: Oil sludge consumed the effective lubricating components in the cutting fluid, increasing metal friction and cutting force, which easily caused tool vibration or dimensional deviation. At the same time, oil sludge provided a breeding ground for anaerobic bacteria (such as sulfate - reducing bacteria), which produced hydrogen sulfide odors and corroded machine tools and workpieces.

Increased operating costs: Frequent shutdowns were required to clean the oil sludge, reducing the effective operating time of the equipment. Additionally, the accumulation of oil sludge shortened the service life of the cutting fluid, increasing procurement and disposal costs.

In summary, prior to partnering with Shenzhen Yuanan Technology, Longfeng's production line faced a series of severe challenges, which are:

Rapid Oxidation: Copper tubes succumbed to visible oxidation shortly after processing, inflating the defect rate to unacceptable levels.

Contamination Issues: The separation of oil sludge in cutting fluids leads to persistent surface contamination, thereby compromising finished product quality, damaging grinding tools, and increasing costs.

Cost Escalation: Frequent rework and scrapping of defective tubes drove up production costs, squeezing profit margins.

Contract Risks: Delays in export deliveries posed a significant threat to maintaining long-term contracts with key clients.

"Our biggest concern was that oxidation and oil sludge issues would damage our reputation as a reliable supplier to global brands," said a senior production manager at Longfeng. "We needed a solution that wasn't just temporary—it had to withstand Southern China's humid conditions, prevent oil sludge separation, and meet our environmental standards."

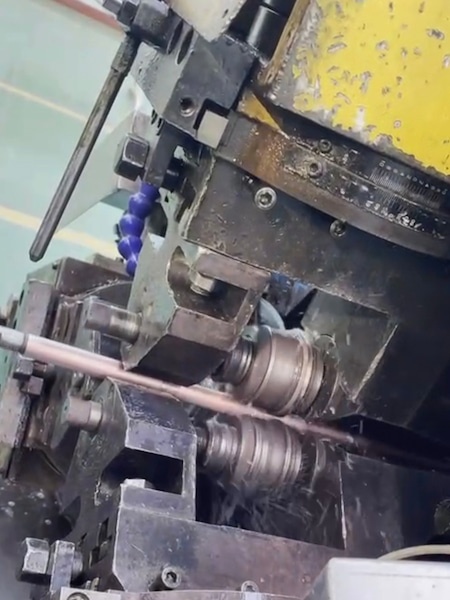

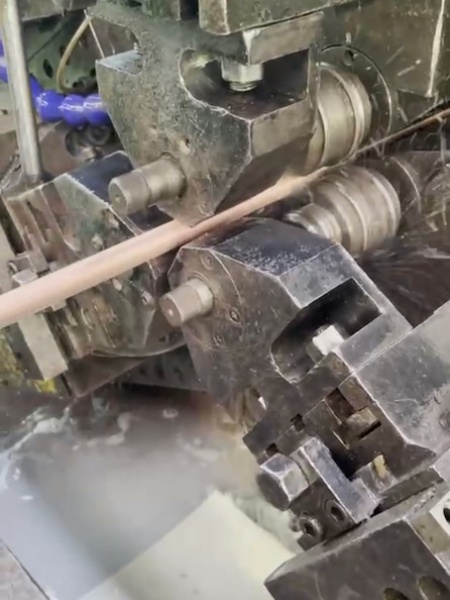

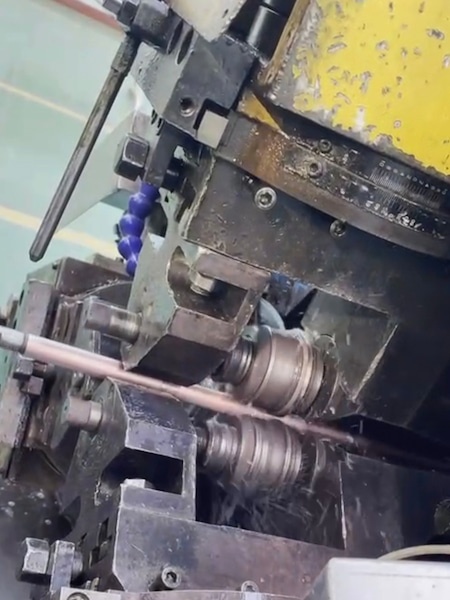

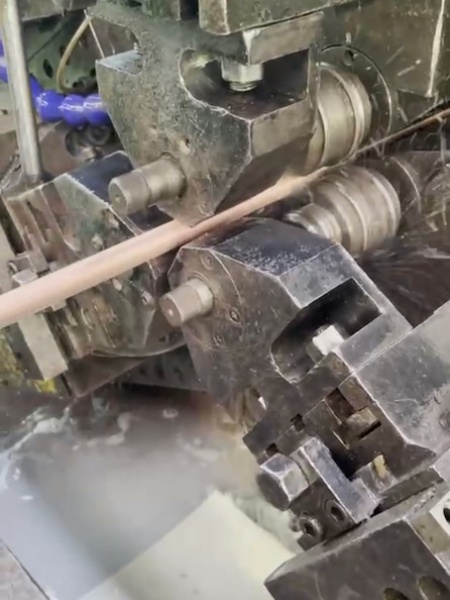

Copper Tube Rolling Process with Industrial Fluid for Anti-Oxidation_Shenzhen Yuanan Chemtech

CNC Machine Copper Tube Machining Using Shenzhen Yuanan Anti Oil Sludge Cutting Fluid

3. Shenzhen Yuanan Chemtech's Solution

Drawing on more than 18 years of R&D experience in precision industrial processing aids, Shenzhen Yuanan Chemtech, a high-tech enterprise with over 60 patents covering cutting, cleaning, and anti-corrosion technologies, first conducted in-depth on-site assessments of Longfeng's production line. We fully understood the pain points of oxidation and oil sludge separation that plagued Longfeng, and also took into account the strict requirements for processing precision and environmental protection in its export business. Based on this, we customized a chlorine-free cutting fluid solution that not only meets the basic functions of high-quality cutting fluids but also targets the core challenges of Longfeng.

Our Shenzhen Yuanan cutting fluid first excels in the three basic functions that all high-performance cutting fluids should have:

Cooling: It can quickly take away the heat generated during copper tube machining, protect both the tool and the workpiece from high - temperature damage—this ensures the dimensional accuracy of the high - precision copper tubes and effectively extends the service life of the cutting tool, reducing the frequency of tool replacement.

Lubrication: It forms a stable lubricating film between the tool and the workpiece, significantly reducing friction during cutting, lowering cutting force, which not only improves the surface finish of the copper tube but also further reduces tool wear.

Flushing: It has strong fluidity and cleaning ability, which can promptly flush away the copper chips and powder generated during processing, ensuring the cleanliness of the machining area and avoiding the interference of cuttings that may damage the machining process and the surface quality of the workpiece.

Beyond these essential basic functions, our cutting fluid is specially optimized to address Longfeng's key pain points: it has excellent anti-oxidation performance and anti-oil sludge generation ability.

Anti-oxidation: It forms a micro-thin, non-toxic protective layer on the surface of the copper tube, which can isolate the humid air during the Meiyu Season (with humidity up to 85%—90%), keeping the copper tube free from oxidation for 15-20 days—far exceeding the industry average of 3-5 days.

Anti-oil sludge generation: We added advanced anti-precipitation and emulsion-stabilizing additives. These additives can inhibit the combination of free copper ions (generated from copper chips) with anions in water to form precipitates, thereby avoiding the disruption of the dissolution equilibrium of calcium and magnesium salts and preventing the "emulsion breaking" of the cutting fluid. This effectively stops the formation of semi-oil and semi-water soap-like oil sludge, ensuring the stability of the cutting fluid throughout the processing cycle.

In addition, this customized cutting fluid also meets Longfeng's environmental protection and export compliance requirements: it contains no chlorine, heavy metals, or phenols, with a VOC content of less than 50g/L and good biodegradability. It fully complies with EU REACH regulations (EC No 1907/2006) , ensuring that the copper tubes processed with this fluid can smoothly pass the environmental compliance inspections of European, North American, and other overseas markets. At the same time, the fluid is highly compatible with Longfeng's existing CNC machining equipment and central fluid supply system, requiring no additional investment in new equipment for adaptation. Its dilution ratio is only 3%—6% (lower than the 8% —10% of ordinary cutting fluids), which can significantly reduce the per-unit use cost of the fluid for Longfeng.

4. Transformative Results for Longfeng

After Longfeng adopted Shenzhen Yuanan Chemtech's chlorine-free cutting fluid solution in 2015, it achieved transformative improvements in production operations and product quality:

Core Pain Points Resolution

Even during the peak Meiyu Season, the copper tubes'oxidation rate plummeted to near zero, and oil sludge separation in the cutting fluid ceased entirely. The defect rate of the copper tubes dropped from its previous high to below 1%, fully complying with the stringent surface quality standards of overseas clients in regions like Europe and North America.

Equipment and Tool Protection

Thanks to the cutting fluid's outstanding cooling and lubricating properties, the service life of the cutting tools was extended by 30% — from the initial 15-day replacement cycle to 20 days. Moreover, the absence of oil sludge prevented wear on precision guide rails, bearings, and hydraulic pumps, reducing equipment maintenance frequency by 25% and prolonging the overall lifespan of the production line.

Production Efficiency and Export Business

Eliminating the rework and scrapping processes for defective tubes saved substantial production time. The stable production process ensured Longfeng's on-time order delivery. What's more, Longfeng successfully fulfilled more additional overseas orders, including a large-scale supply contract for BYD's European EV air conditioning copper tubes, further expanding its market share in the high-end copper tube sector.

Cost Control

With a service life six times that of ordinary fluids and a low dilution ratio, the cutting fluid significantly reduced annual procurement and disposal costs. Combined with decreased tool replacement and equipment maintenance costs, Longfeng's overall annual production costs decreased, notably enhancing its profit margin.

"We didn't just purchase a cutting fluid from Shenzhen Yuanan Chemtech—we gained a comprehensive production optimization solution," said the senior production manager at Longfeng. "When we first encountered the oxidation and oil sludge problems, their team responded to our request within 72 hours, arrived at the site for debugging, and even provided monthly follow-up maintenance and technical guidance later. This professional and responsible service made them our most trusted partner in the field of industrial chemicals."

For Shenzhen Yuanan Chemtech, the successful cooperation with Longfeng (Golden Dragon Group) is a vivid practice of our concept of "solving industry pain points with technology". As a high-end provider of industrial processing aids focusing on semiconductor, new energy, and precision manufacturing fields, we have always adhered to the R&D concept of "taking customer needs as the core". Through our OEM/ODM capabilities and ISO 9001/14001-certified production system, we are committed to providing customized, high-performance, and compliant solutions for global clients, helping them overcome production challenges and achieve sustainable development.

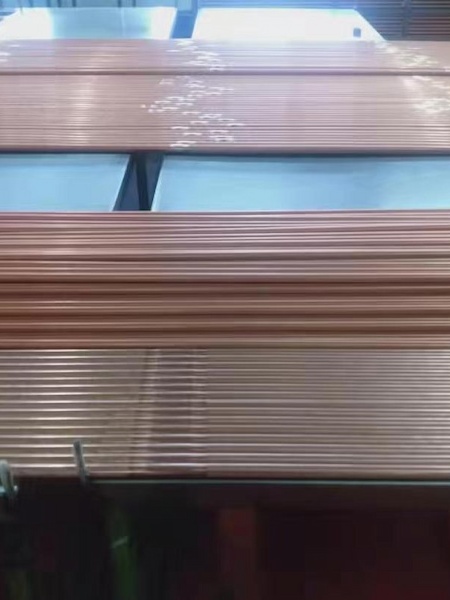

Emulsion Stable Copper Tube Processing With Shenzhen Yuanan Cutting Fluid

Copper Tube No Emulsion Breaking Effect With Shenzhen Yuanan Cutting Fluid

5. Invitation for Cooperation

If your enterprise is also engaged in the production of copper tubes (especially for HVAC, EV air conditioning, refrigeration, and other high-end fields) and faces challenges such as copper tube oxidation, cutting fluid oil sludge separation, insufficient machining precision, or failure to meet overseas environmental compliance standards, Shenzhen Yuanan Chemtech is ready to provide you with professional support:

You can request a free sample of our chlorine-free cutting fluid to conduct small-batch trial tests in your production line, verifying its performance in cooling, lubrication, anti-oxidation, and anti-oil sludge.

We can also provide you with a customized solution proposal—our technical team will conduct in-depth communication with you to understand your specific production processes, equipment models, and quality requirements, and tailor the most suitable cutting fluid formula and use plan for you.

In addition, you can contact us to obtain the MSDS summary of our cutting fluid products, and visit our official website, which details the product's environmental indicators, safety performance, and compliance certifications (including REACH, RoHS), helping you quickly confirm whether it meets your market access requirements. To learn more about how our cutting fluid solutions can help your enterprise improve product quality, reduce production costs, and expand global markets, reach out to our team today via our email at [contact@yuananchemtech.com].We look forward to becoming your long-term strategic partner in the precision manufacturing field.

We look forward to becoming your long-term strategic partner in the precision manufacturing field.

Oil Sludge Free Copper Tube Surface After Using Shenzhen Yuanan Cutting Fluid

Hard Water Resistant Copper Tube Effect With Shenzhen Yuanan Cutting Fluid

6. FAQ: Shenzhen Yuanan Chemtech's Chlorine-Free Cutting Fluid

6.1 Compatibility with Copper Tube Machining for HVAC and EV Fields

Q: Our enterprise mainly produces high-precision copper tubes for HVAC systems and EV air conditioning. Is your chlorine-free cutting fluid suitable for our machining processes?

A: Hello! Our chlorine-free cutting fluid is fully suitable for the machining of high-precision copper tubes in HVAC and EV air conditioning fields. It supports core processes such as cutting, drilling, and grinding of mainstream copper tube types (Type L, M, K). It not only has excellent cooling, lubrication, and flushing functions to ensure machining precision and tool life but also can effectively prevent copper tube oxidation and cutting fluid oil sludge generation. It is currently used by clients such as Longfeng (Golden Dragon Group) for the production of copper tubes supplied to BYD and European HVAC brands, fully meeting the high standards of these fields.

6.2 Effect on Improving the Surface Quality of Exported Copper Tubes

Q: Most of our copper tubes are exported to Europe and North America, and clients have very strict requirements on the surface quality of the tubes (no oxidation, no oil stains). Can your cutting fluid help us meet these requirements?

A: Hello! Yes. Our cutting fluid's anti-oxidation performance can form a protective layer on the copper tube surface to avoid oxidation even in high-humidity environments like the Meiyu Season. At the same time, its anti-oil sludge function prevents oil sludge from adhering to the tube surface, ensuring no oil stains or scratches on the copper tube surface after machining. In the cooperation with Longfeng, the surface defect rate of their exported copper tubes dropped to less than 1%, and all batches passed the inspection of European and North American clients. Using our cutting fluid can help your products stably meet overseas surface quality standards.

6.3 Compliance with International Environmental Standards

Q: We plan to expand the Southeast Asian market. Does your chlorine-free cutting fluid comply with the environmental protection regulations of Southeast Asian countries, as well as EU REACH and U.S. EPA standards?

A: Hello! Our chlorine-free cutting fluid is designed with global environmental compliance in mind. It contains no chlorine, heavy metals, or phenols, has low VOC content, and is biodegradable. It has passed the certification of EU REACH regulations (EC No 1907/2006). At the same time, it also complies with the environmental protection standards of major Southeast Asian countries (such as Thailand, Malaysia, Indonesia, etc.). Copper tubes processed with this fluid can smoothly pass the environmental compliance inspection of target markets, providing a guarantee for your market expansion.

6.4 Service Life and Cost-Saving Effect of the Cutting Fluid

Q: We are very concerned about the service life of the cutting fluid and its cost-saving effect. How does your product perform in these aspects?

A: Our chlorine-free cutting fluid has a long service life. Thanks to its excellent stability and anti-deterioration formula, it can maintain effective performance for 3-6 months under normal operating conditions, reducing the frequency of fluid replacement. In terms of cost-saving, although the initial purchase price may seem slightly higher, its high efficiency reduces tool wear and improves machining precision, minimizing rework and scrap rates. In actual use cases, customers have reported an average reduction in overall machining costs by 15%—20% compared to traditional cutting fluids.

6.5 Ease of Use and Compatibility with Existing Equipment

Q: We already have established copper tube machining equipment. Will your cutting fluid require any special modifications to our existing setup?

A: Our chlorine-free cutting fluid is highly compatible with most standard copper tube machining equipment. There is generally no need for major modifications to your existing setup. It can be easily integrated into your current machining process, and our technical team can provide on-site guidance if needed to ensure a smooth transition. Just follow the recommended dilution ratio and usage instructions, and you can start using it right away.

6.6 Technical Support and After-Sales Service

Q: What kind of technical support and after-sales service can we expect after purchasing your cutting fluid?

A: We offer comprehensive technical support and after-sales service. Our professional technical team is here to answer any questions you may have during the use of the product. We can also provide on-site technical training for your operators to ensure they use the cutting fluid correctly. In case of any issues, we will respond within 24 hours and send technicians to your site if necessary to solve problems promptly, ensuring minimal disruption to your production process.