Wafer slicing, especially in advanced semiconductor manufacturing, is a highly delicate process where every micron counts. Multi-wire sawing and diamond wire cutting are standard methods, but they present persistent challenges such as wire wear, total thickness variation (TTV), micro-cracks, and surface contamination. Engineers and R&D teams are constantly seeking process-level solutions to optimize yields and protect both wafers and equipment. Non-Corrosive Precision Cutting Fluid for Wafers from Shenzhen Yuanan Technology Co., Ltd. offers targeted improvements, addressing cooling, lubrication, and particle management, while safeguarding sensitive materials like LED wafers and brittle ceramic substrates. By selecting the right cutting fluid, production teams can significantly reduce downtime, improve equipment lifespan, and enhance overall wafer quality—a crucial advantage in high-volume, high-precision operations.

How Cutting Fluid Interacts with the Diamond Wire Process

Cooling vs Lubrication: Managing Heat and Friction

In diamond wire slicing, controlling both heat and friction is critical. Excessive heat can lead to wire elongation, reduced cutting accuracy, and thermal stress on the wafer. Lubrication, on the other hand, minimizes friction between the diamond-coated wire and the wafer surface, reducing wire wear and prolonging equipment life. A high-performance wafer slicing coolant must balance both functions—extracting heat efficiently while maintaining a lubricating film along the wire. Non-Corrosive Precision Cutting Fluid for Wafers achieves this dual role, maintaining stable wire performance and consistent surface finish even during high-throughput production runs.

Additionally, cutting fluid viscosity influences how effectively the wire moves through the wafer. Fluids with too low viscosity may fail to provide sufficient lubrication, causing micro-chipping, while overly viscous fluids can lead to drag, reducing feed rate and productivity. Yuanan Technology’s precision fluid is formulated to maintain optimal viscosity under varying temperatures, ensuring a consistent cutting environment and protecting wafer surfaces throughout the slicing process.

Anti-Adsorption and Particle Management

Silicon dust and debris generated during cutting can easily redeposit on the wire or wafer surface, causing scratches, micro-cracks, and increased TTV. Advanced cutting fluids incorporate anti-adsorption properties that prevent particle accumulation and enable smooth transport of debris away from the cutting zone. This functionality reduces downstream cleaning requirements and lowers the risk of contamination. Yuanan Technology’s formulation also maintains consistent viscosity and particle suspension, ensuring that even ultrathin wafers remain protected throughout the slicing process.

Beyond preventing redeposition, effective particle management also reduces the risk of clogging in high-precision cutting equipment. Accumulated debris can impede wire movement, requiring unscheduled maintenance. Non-Corrosive Precision Cutting Fluid for Wafers keeps particles in suspension long enough to be filtered out, promoting uninterrupted operation and protecting both the wire and wafers.

Process Parameters to Tune When You Switch Fluids

Wire Tension and Feed Rate

Switching to a non-corrosive precision fluid often requires adjustment of wire tension and feed rate. Optimizing these parameters ensures that the wire maintains adequate contact with the wafer without generating excess stress. A recommended approach involves iterative measurement: begin with manufacturer-recommended settings, monitor wire wear and TTV, and adjust feed rate incrementally. Slight increases in lubrication from the fluid may allow slightly higher feed rates without compromising wafer quality, improving throughput.

Engineers should also consider the interaction between wire tension and wafer thickness. Thin wafers are more sensitive to tension variations, and small adjustments in feed rate can have an outsized impact on crack formation and surface integrity. Non-Corrosive Precision Cutting Fluid for Wafers helps mitigate these risks by providing stable lubrication and minimizing thermal expansion effects.

Flow Rate and Filtration

Fluid circulation and filtration play crucial roles in maintaining a clean cutting environment. Closed-loop systems with high-efficiency filters remove micro-particles that can scratch wafers or abrade wires. Maintaining an optimal flow rate ensures that the fluid efficiently removes debris while evenly cooling the wire and wafer. Non-Corrosive Precision Cutting Fluid for Wafers is designed for stable suspension and low residue, reducing the frequency of filter changes and minimizing production downtime.

Continuous monitoring of flow rate and pressure in the delivery system is recommended, especially when processing large batches or switching wafer types. Properly tuned flow ensures even cooling and prevents localized overheating, which can otherwise lead to warping or micro-cracks in sensitive materials.

Temperature Control and Thermal Cycling

High heat stability is essential, particularly when processing LEDs or ceramics that are sensitive to temperature fluctuations. Temperature control ensures uniform expansion and contraction of the wafer, preventing warping and micro-cracks. Non-Corrosive fluids are less prone to chemical degradation under thermal cycling, maintaining consistent viscosity and lubrication over long production periods, which protects both equipment and wafers from thermal stress.

For advanced manufacturing environments, combining fluid with precise thermal management systems allows engineers to simulate production conditions and optimize cutting parameters. This approach reduces yield loss due to thermal effects and helps maintain long-term wire consistency across multiple production cycles.

Real-World Troubleshooting

Wire Glazing or Rapid Wear

If the diamond wire shows glazing or rapid wear, the cause is often insufficient lubrication or fluid breakdown. Adjusting fluid concentration to increase lubricity or switching to a high-performance non-corrosive formula can mitigate this issue. Regular monitoring of wire wear patterns, combined with precise fluid management, ensures consistent cutting performance.

Unwanted Corrosion or Etch Marks

Even small traces of incompatible chemicals or contaminants in the coolant can cause surface etching or corrosion marks on wafers. Non-Corrosive Precision Cutting Fluid for Wafers is formulated to prevent such reactions, protecting sensitive LED or ceramic surfaces. Regular maintenance of tanks and avoiding cross-contamination ensures maximum fluid effectiveness.

Biological Growth in Coolant Tanks

In production environments where fluid is recirculated, microbial growth can become an issue, impacting both fluid quality and wafer cleanliness. Incorporating biocide strategies and maintaining filtration are effective measures. Yuanan Technology’s cutting fluids are compatible with biocides and are designed to resist microbial proliferation, ensuring a safer and cleaner operational environment.

Case Scenario: LED Wafers vs Ceramic Substrates

LED Wafers: Contamination Sensitivity

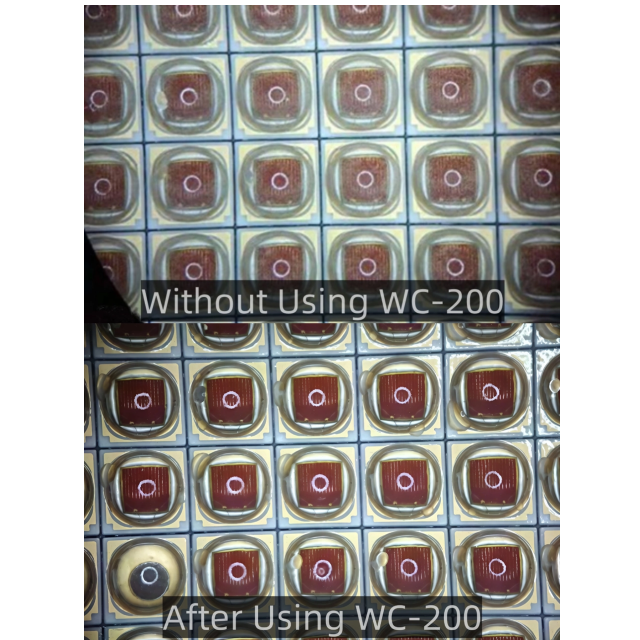

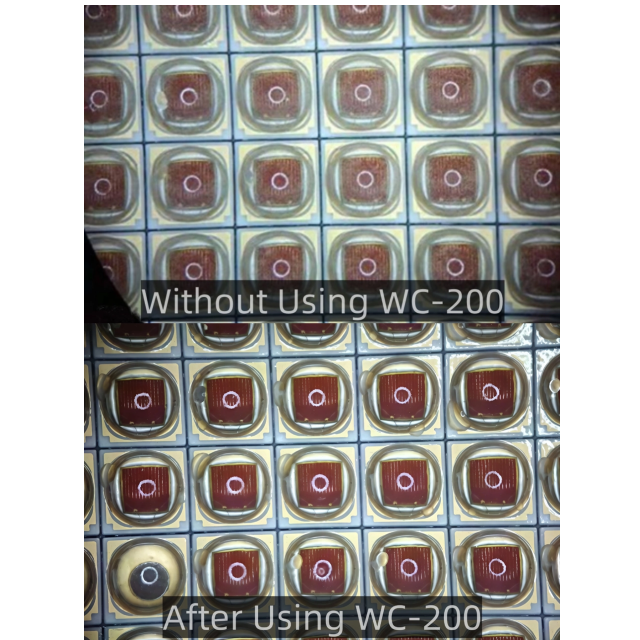

LED wafers are highly sensitive to surface contamination. Even minimal silicon dust re-deposition can necessitate additional cleaning, increasing production costs and reducing yield. Non-Corrosive Precision Cutting Fluid for Wafers minimizes particle adhesion and maintains a chemically inert cutting environment, reducing post-slice cleaning and maximizing throughput.

Ceramic Substrates: Fragility and Lubricity

Ceramic substrates are brittle and prone to cracking if cutting forces are uneven. Here, fluid lubricity is critical to absorbing micro-stresses and preventing surface chipping. A non-corrosive, thermally stable fluid ensures that even hard ceramics are sliced smoothly, maintaining structural integrity and reducing scrap rates.

How to Run a Production Trial

Suggested Metrics

To evaluate a new cutting fluid, measure total thickness variation (TTV), warp, wire life, scrap rate, and cleaning time. Monitoring these metrics provides clear data on the fluid’s impact on process stability and wafer quality. Recording additional parameters such as fluid temperature, pH, and particle load further refines process control and ensures reproducible results.

Minimal Trial Plan

A practical trial can begin with a small batch of representative wafers over a limited time window. Collect real-time data using templates for feed rate, wire tension, and fluid parameters. Iterative analysis allows fine-tuning of fluid concentration, flow rate, and temperature settings before scaling up to full production. This structured approach ensures measurable improvements and reduces operational risks.

Conclusion

Non-Corrosive Precision Cutting Fluid for Wafers from Shenzhen Yuanan Technology Co., Ltd. provides comprehensive benefits across wafer types, from LEDs to ceramics. By optimizing cooling, lubrication, and particle management, it improves wire life, reduces TTV and micro-cracks, and minimizes contamination and cleaning costs. Engineers can expect enhanced throughput, lower scrap rates, and greater consistency in wafer quality. To explore detailed technical data sheets, MSDS, or request trial samples, contact us directly. Investing in the right cutting fluid transforms wafer slicing into a more predictable, efficient, and cost-effective process, ensuring your production meets the highest precision standards.