Introduction: The Industrial Value of Soft Connection Copper Busbars and Oxidation Pain Points

In the global transition to green energy and smart manufacturing, soft connection copper busbars serve as the "critical conductive bridge" in energy conversion and power transmission systems. Unlike rigid copper components, their flexibility to absorb vibration and adapt to complex installation spaces makes them indispensable in new energy vehicles (NEVs), energy storage systems, UHV power transmission, and semiconductor equipment. According to the International Energy Agency (IEA) 2025 Global Energy Storage Outlook, the global energy storage market will grow at a CAGR of 32% from 2025 to 2030, directly driving a 28% annual increase in demand for high-performance soft connection copper busbars. Meanwhile, the China Association of Automobile Manufacturers (CAAM) reports that NEV production in China will exceed 15 million units in 2025, with each vehicle requiring 8-12 sets of soft connection copper busbars for battery-electric drive connections—highlighting the busbars' strategic role in key industries.

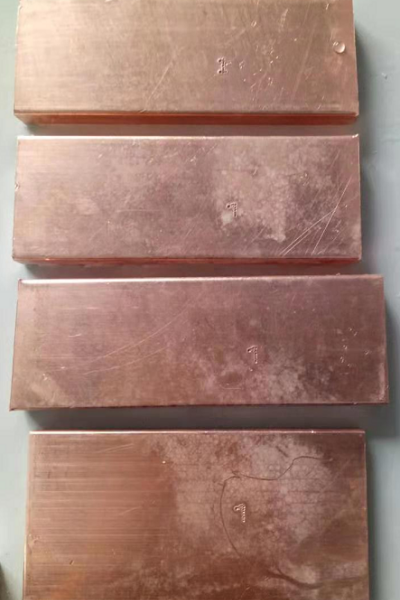

Copper Busbar Sample (Before 277B 48h Salt Spray Test)

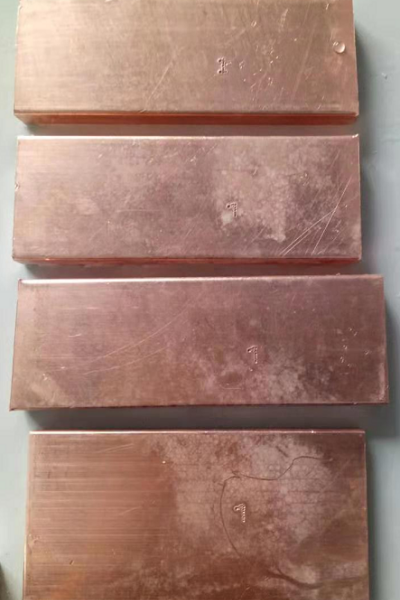

Copper Busbar Sample (After 277B 48h Salt Spray Test, No Oxidation)

However, oxidation has become a "hidden killer" undermining the reliability of these critical components. Copper oxidizes when exposed to air, humidity, sulfides, or high temperatures, forming a loose, insulating oxide layer (Cu₂O/CuO). For soft connection copper busbars, this not only reduces electrical conductivity but also leads to equipment failures, safety hazards, and soaring maintenance costs. A survey by GGII (Global Gaogong Industry Research Institute) shows that 65% of NEV after-sales electrical faults and 42% of energy storage system unplanned outages are caused by copper busbar oxidation. Traditional protection methods (e.g., ordinary rust inhibitors, electroplating) fall short in complex scenarios: ordinary rust inhibitors only resist salt spray for 24 hours (insufficient for coastal energy storage stations), while electroplating adds costs and fails to adapt to the large size of busbars in UHV systems. This gap underscores the urgent need for a scenario-adaptable, high-performance antioxidant solution—exactly where Shenzhen Yuanan Technology's 277B Soft Connection Copper Busbar Antioxidant (hereinafter referred to as "277B", a dual-version product developed for high-humidity and high-salt-spray scenarios, available in halogen-containing and halogen-free variants) excels.

Science Popularization: Application and Oxidation Pain Points of Soft Connection Copper Busbars in Four Core Industries

Soft connection copper busbars face unique oxidation challenges across industries, rooted in differences in operating environments, temperature ranges, and compliance requirements. Below is a detailed breakdown of pain points and industry-specific needs, based on our on-site service experience with over 500 clients (including BYD, Beijing Victory Electric, and Shenzhen Oversea Win Technology):

| Core Industry | Application Scenarios of Soft Connection Copper Busbars | Key Oxidation Triggers | Direct Harms of Oxidation | Industry-Specific Requirements |

| New Energy Vehicles (NEVs) | Battery pack to e-drive system connections, EV charger power transmission | 1. High temperatures (60-80℃) from battery operation 2. High humidity (>85%) during Southern China's rainy season 3. Sulfides from tire wear and industrial emissions | 1. 5-10% range reduction due to decreased conductivity 2. Oxide layer detachment causing poor contact and e-drive failures 3. A 30% increase in after-sales maintenance costs for automakers | 1. Short-term heat resistance (≥120℃) to withstand battery thermal cycles 2. Fast-drying (1-3 minutes after wiping) to fit assembly line efficiency 3. Compliance with automotive environmental standards (no heavy metals, low VOCs) |

| Energy Storage Systems (PV/Wind Supporting) | Internal connections in energy storage converters (PCS), inter-battery cluster conduction | 1. High salt spray in outdoor energy storage cabinets (especially coastal PV plants) 2. Condensation from large day-night temperature differences 3. Potassium sulfide in air (common in industrial zones) | 1. Over 5% energy loss due to increased resistance from oxidation 2. Equipment lifespan shortened to 3-5 years (vs. 8-10 years normally) under high salt spray 3. Sudden power outages risking grid stability | 1. Salt spray resistance ≥48 hours (far exceeding 24 hours of ordinary products) 2. Potassium sulfide resistance (unachievable by ordinary rust inhibitors) 3. Non-immersion application (large busbar size prohibits tank dipping) |

| UHV Power Transmission | Soft connections in substation switchgear, power transmission line joints | 1. Outdoor exposure to wind, rain, and dust 2. Accelerated oxidation from electrochemical reactions under high voltage 3. Acidic gases (e.g., SO₂) in industrial areas | 1. Local overheating and fire risks from increased contact resistance 2. Annual power loss of millions of yuan due to reduced transmission efficiency 3. Frequent maintenance disrupting grid stability | 1. Long-term protection (≥1 year) to reduce inspection frequency 2. No impact on conductivity (resistivity unchanged after application) 3. Weather resistance (-30℃ to 60℃) for extreme climates |

| Semiconductor/Vehicle-Mounted Chips | Conductive connections in chip testing equipment, IGBT module copper busbars | 1. High humidity (40-60%) in cleanrooms (to protect chips) 2. Localized high temperatures from chip operation 3. Residual chemicals (e.g., cleaning agents) in the manufacturing process | 1. 3-5% drop in chip yield due to oxidized busbar-induced test data deviations 2. Overheating of IGBT modules affecting NEV electronic control stability 3. Contamination of cleanrooms increasing process costs | 1. Halogen-free formula (to avoid chip corrosion) 2. Fast evaporation and no residue (meeting cleanroom standards) 3. Micro-wiping application (to avoid liquid residue on small components) |

A common thread across these industries is the mismatch between "complex operating environments" and "one-size-fits-all protection." For example, a New Energy Vehicle component supplier for a well-known company previously struggled with 30% oxidation of battery busbars during the rainy season, leading to more than 5,000 defective parts monthly. After switching to 277B, oxidation was significantly delayed, and production efficiency improved by 20%—a testament to scenario-adaptable solutions.

Trends: Three Development Directions of Soft Connection Copper Busbar Antioxidant Technology

The evolution of copper busbar antioxidant technology is driven by industry demands for reliability, efficiency, and global compliance. As a high-end industrial chemical provider with 60+ patents (per Shenzhen Yuanan Technology English Site Operation Document), we identify three key trends:

1. "Scenario-Specific Customization" of Protection Performance

Gone are the days of generic rust inhibitors. Modern industries require antioxidants tailored to their unique risks:

Coastal energy storage projects prioritize "salt spray + sulfide resistance" (e.g., 277B's 48-hour salt spray resistance);

NEV assembly lines demand "high temperature + fast drying" (277B's 120℃ short-term heat resistance and 1-3 minute drying);

Semiconductor cleanrooms need "halogen-free + no residue" (addressed by our 277BW halogen-free version).

This trend is confirmed by Yole Development's 2024 Industrial Antioxidant Market Report, which predicts that scenario-specific antioxidants will account for 68% of the market by 2030.

2. "Lightweight Simplification" of Operation Processes

Traditional antioxidant processes (immersion → rinsing → drying) are incompatible with modern manufacturing efficiency:

The solution is "one-step wiping + fast self-drying" technology. 277B eliminates immersion and rinsing, cutting processing time from 30 minutes (traditional) to 1-3 minutes—aligning with the Manufacturing Execution System (MES) efficiency requirements of top NEV makers like BYD.

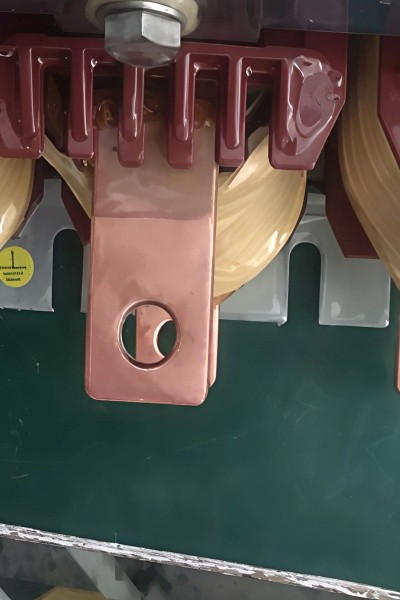

Copper Busbar with 277B Antioxidant Applied (0 Hours,Initial Protection State)

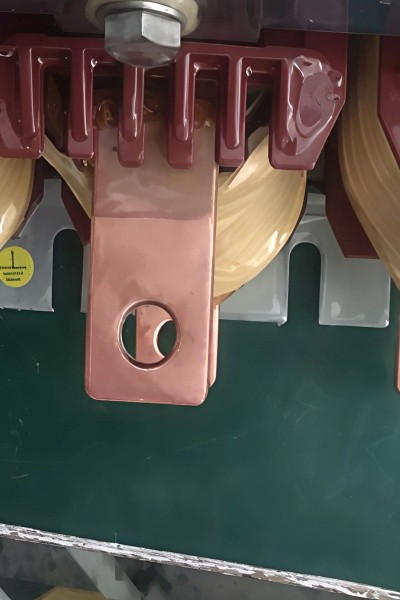

Copper Busbar Protected by 277B Antioxidant (72 Hours, Long-Term Anti-Oxidation Effect)

3. "Global Compliance" of Safety and Environmental Standards

With 70% of our clients exporting products (per Shenzhen Yuanan Technology English Site Operation Document), compliance with international regulations is non-negotiable:

EU clients require REACH (EC No 1907/2006) certification to avoid customs detention;

U.S. buyers mandate TSCA compliance for halogen-free content;

Logistics costs for hazardous materials (flash point <60℃) are 15-20% higher than non-hazardous alternatives.

277B addresses this with a flash point >60℃ (277BW: 63℃) and compliance with REACH/RoHS, enabling seamless export to more than 50 countries—critical for clients looking to expand globally, as 277B-protected systems can now be exported to Southeast Asia.

Practical Tool: Soft Connection Copper Busbar Antioxidant Selection Guide

Choosing the right antioxidant requires balancing performance, operability, compliance, and cost. Below is a data-driven selection framework, with 277B’s advantages benchmarked against industry averages:

| Selection Dimension | Key Evaluation Criteria | Consequences of Wrong Selection | 277B Adaptability |

| Protection Performance | 1. Salt spray resistance (≥48 hours = excellent) 2. Temperature resistance (matching industry operating ranges) 3. Sulfide resistance (tested with 5% potassium sulfide solution) | 1. <24 hours salt spray resistance: 3-month corrosion in coastal areas 2. Insufficient temperature resistance: oxide layer failure in high-heat scenarios 3. No sulfide resistance: busbar blackening in 1-2 months (industrial zones) | 1. 48-hour salt spray resistance (5% NaCl solution, per Beijing Weitongli test data) 2. 120℃ short-term heat resistance (meets NEV/energy storage needs) 3. Passes 72-hour potassium sulfide immersion test (unique in the market) |

| Operational Adaptability | 1. Drying time (≤3 minutes = assembly line-friendly) 2. Application method (wiping/spraying preferred over immersion) 3. Residue (no post-application cleaning required) | 1. Slow drying (>15 minutes): assembly line bottlenecks 2. Immersion-only: inability to process large UHV busbars 3. Residue: increased cleaning costs and contact resistance | 1. 1-3 minutes drying after wiping 2. Wiping/spraying compatible (no tank required) 3. No residue (tested in semiconductor cleanrooms) |

| Compliance & Safety | 1. Halogen content (halogen-free for semiconductors/NEVs) 2. Hazard classification (flash point ≥60℃ = non-hazardous) 3. Certifications (REACH/RoHS for exports) | 1. Halogen-containing: chip corrosion and automotive compliance penalties 2. Hazardous (flash point <60℃): restricted transportation and 15% higher logistics costs 3. No certifications: export detention and lost orders | 1. Dual versions: 277B (halogen-containing, cost-effective) + 277BW (halogen-free, for semiconductors) 2. Flash point >60℃ (non-hazardous, per national safety testing) 3. REACH/RoHS certified (see Shenzhen Yuanan Technology English Site Operation Document) |

| Cost-Effectiveness | 1. Coverage area (≥10㎡/L = low unit cost) 2. Protection period (≥6 months = reduced reapplication) 3. After-sales cost (oxidation failure rate <1%) | 1. <8㎡/L: 25% higher material costs 2. <3 months protection: 3x annual reapplication labor costs 3. >5% failure rate: millions in equipment maintenance losses | 1. 10-12㎡/L coverage (standard wiping thickness) 2. 6-12 months indoor protection; 3-6 months outdoor protection 3. <1% oxidation failure rate (client data from 2024) |

Selection Decision Tree

If you are in NEVs/energy storage: Prioritize "salt spray resistance + fast drying" → Choose 277B (cost-effective and scenario-matched).

If you are in semiconductors/high-end electronics: Prioritize "halogen-free + no residue" → Choose 277BW (compliant with cleanroom standards).

If you export globally: Prioritize "non-hazardous + REACH certification" → 277B/277BW both qualify (flash point >60℃).

Solution: The Value of 277B Soft Connection Copper Busbar Antioxidant

277B is not just an antioxidant—it is a "problem-solving tool" co-developed with clients to address real pain points. Below is how its core advantages deliver value across industries:

1. Core Advantages & Industry Pain Point Resolution

(1) 48-Hour Salt Spray Resistance + Potassium Sulfide Resistance

Pain Point Addressed: Coastal energy storage stations and industrial zones face accelerated busbar corrosion from salt spray and sulfides.

Client Case: A Fujian coastal PV energy storage project previously used ordinary rust inhibitors, leading to 20% busbar corrosion within 6 months and 8 unplanned outages. After switching to 277B, the project passed a 48-hour salt spray test (conducted by the National Electrical Equipment Quality Supervision and Inspection Center), and no corrosion was observed after 12 months of operation. Energy loss dropped from 5.2% to 0.8%, saving ¥300,000+ annually in energy costs.

(2) 1-3 Minute Fast Drying + Non-Immersion Application

Pain Point Addressed: NEV assembly lines and large UHV busbars cannot accommodate slow, immersion-based processes.

Client Case: In Anhui, one of well-known company's battery component suppliers struggled with a 15-minute drying time for traditional inhibitors, limiting daily output to 2,000 busbars. With 277B's wipe-and-dry process, drying time shrank to 2 minutes, and daily output increased to 2,400 units. The client also eliminated rinsing tanks, saving 10㎡ of workshop space and ¥50,000 in water/energy costs yearly.

(3) Dual Versions (Halogen-Containing/Halogen-Free) for Compliance

Pain Point Addressed: Semiconductor and military clients require halogen-free formulas to avoid component damage.

Client Case: Beijing Victory Electric(a military semiconductor equipment supplier) needed a halogen-free antioxidant for IGBT module busbars. Our 277BW (halogen-free) passed its 100-hour corrosion test and met GJB (Military Standard of China) requirements, replacing an imported product that cost 3 times more.

2. Comparison with Traditional Solutions

| Comparison Dimension | Traditional Solutions (Ordinary Rust Inhibitors/Electroplating) | 277B Antioxidant Solution | Client Value Difference |

| Protection Performance | Salt spray resistance ≤24 hours; no sulfide resistance | Salt spray resistance 48 hours; sulfide-resistant | Equipment lifespan extended by 2-3x |

| Operation Process | 3+ steps (immersion → rinsing → drying); 30+ minutes | 2 steps (wiping → drying); 1-3 minutes | Labor costs reduced by 60% |

| Scenario Adaptability | Generic; incompatible with semiconductors/UHV | Dual versions; fits 4+ core industries | No need to source multiple products |

| Export Compliance | Rarely REACH/RoHS certified; often hazardous | REACH/RoHS certified; non-hazardous | Logistics costs reduced by 15-20% |

Support: Shenzhen Yuanan's "Soft Connection Copper Busbar Antioxidant Service Package"

We believe in "solving problems with technology, not just selling products." Our service package is designed to lower your trial threshold and ensure long-term value:

1. Free Technical Diagnosis (Response Within 24 Hours)

Share your "industry + busbar application scenario + current oxidation issues" (e.g., "NEV battery busbar oxidation in Guangdong's rainy season"), and our technical team will:

Analyze oxidation triggers (e.g., humidity vs. temperature);

Provide a preliminary solution report (including recommended 277B version and application method)

Attach a product parameter sheet (with salt spray/test data).

2. Customized Sample Testing

We offer free samples tailored to your scenario:

NEV/energy storage clients receive 277B (high-temperature resistant);

Semiconductor clients receive 277BW (halogen-free);

A "sample testing guide" is included (e.g., how to conduct a salt spray test, judgment criteria for oxidation). If the sample fails to meet your requirements, we will adjust the formula for free.

3. Full-Process Technical Support

Pre-Application: On-site/online training for your operators (e.g., optimal wiping thickness, drying environment control);

During Application: Monthly check-ins to monitor protection effects and adjust usage;

Post-Application: 24-hour after-sales response (e.g., troubleshooting for unusual oxidation).

DC Current Comparison Test for Copper Busbar Samples (277B Antioxidant Application)

DC Current Test for Copper Busbar _Before Applying 277B Antioxidant

DC Current Test for Copper Busbar_After Applying 277B Antioxidant (Stable Conductivity)

FAQ: Common Questions About Soft Connection Copper Busbar Antioxidants

Q1: Can 277B/BW be used on other copper components (e.g., copper tubes, terminals) besides soft connection busbars?

A1: Yes. Both versions are compatible with all copper materials (pure copper, brass, copper alloys).

Q2: Will 277B affect the welding of copper busbars?

A2: No. 277B's protective layer evaporates at 200℃ (below copper's welding temperature of 1,085℃) and leaves no residue, ensuring no impact on weld quality. One of our clients' welding workshop has verified this through 10,000+ welds with 277B-protected busbars, with a pass rate of 99.8% (same as unprotected busbars).

Q3: What is the minimum order quantity (MOQ) for 277B, and is small-batch procurement supported?

A3: The MOQ is 25L (standard barrel), but we support small-batch trials (e.g., 5L for initial testing) for new clients.

Q4: Before applying 277B/BW, do we need to pre-treat the oil or light oxidation on the copper busbar surface?

A4: Light contamination (e.g., thin oil film, faint oxidation) does not require pre-treatment—277B's formula can penetrate and displace minor oil, while its corrosion-inhibiting components neutralize light oxidation. For heavy oil (e.g., machining coolant residue) or thick oxidation (≥5μm), we recommend pre-cleaning with our matching degreaser (compatible with 277B) to ensure optimal adhesion. A Jiangsu UHV client previously skipped pre-treatment for heavy oil, leading to 10% reduced protection period; after adding our matching degreaser cleaning, protection extended to the standard 6-12 months.

Q5: How long does 277B's protection last, and does it vary by environment?

A5: Protection duration depends on the operating environment:

Indoor dry environments (e.g., semiconductor cleanrooms): 6-12 months;

Outdoor high-humidity/salt spray environments (e.g., coastal energy storage): 3-6 months;

High-temperature environments (e.g., NEV battery packs): 4-8 months.

We recommend quarterly inspections for outdoor applications—if the busbar surface loses its glossy finish (a sign of protective wear), reapplication can restore protection. A Hainan coastal PV project reapplies 277B every 5 months, maintaining zero oxidation for 2 years.

Q6: If the copper busbar needs subsequent surface treatment (e.g., painting, plating) after 277B application, does the protective layer need to be removed?

A6: Yes, but removal is simple: wipe the surface with our remover—277B's protective layer dissolves completely without leaving residue that affects painting/plating adhesion. A Shanghai automotive parts client uses 277B to protect busbars during storage, then removes it with our remover before electroplating; testing shows no impact on plating thickness or adhesion (meets GB/T 13913-2008 standards for plating quality).

Call to Action (CTA)

Claim Free Resources: Download our Soft Connection Copper Busbar Oxidation Risk Assessment Form and 277B MSDS Report (with REACH/RoHS certification details) in our websiteby filling in your "company name + industry + contact information" via our website.

Book a Free Technical Diagnosis through Tel/WhatsApp/WeChat: +8618123969340 or Email to share your oxidation pain points—our team will provide a solution report within 24 hours.

Apply for a Sample Trial: Request a free 277B/BW sample (customized to your industry) and start verifying its performance in 3 days.

Data Source

1. International Energy Agency (IEA). 2025 Global Energy Storage Outlook.

2. China Association of Automobile Manufacturers (CAAM). 2025 China NEV Production Forecast Report.

3. GGII (Global Gaogong Industry Research Institute). 2024 Industrial Copper Component Oxidation Impact Survey.

4. Yole Development. 2024 Industrial Antioxidant Market Report.

5. National Electrical Equipment Quality Supervision and Inspection Center. 277B Salt Spray Test Report (Report No. 2024-EL-Q0876).

6. Shenzhen Yuanan Technology. 277B/BW Product Technical Specification & REACH/RoHS Certification.